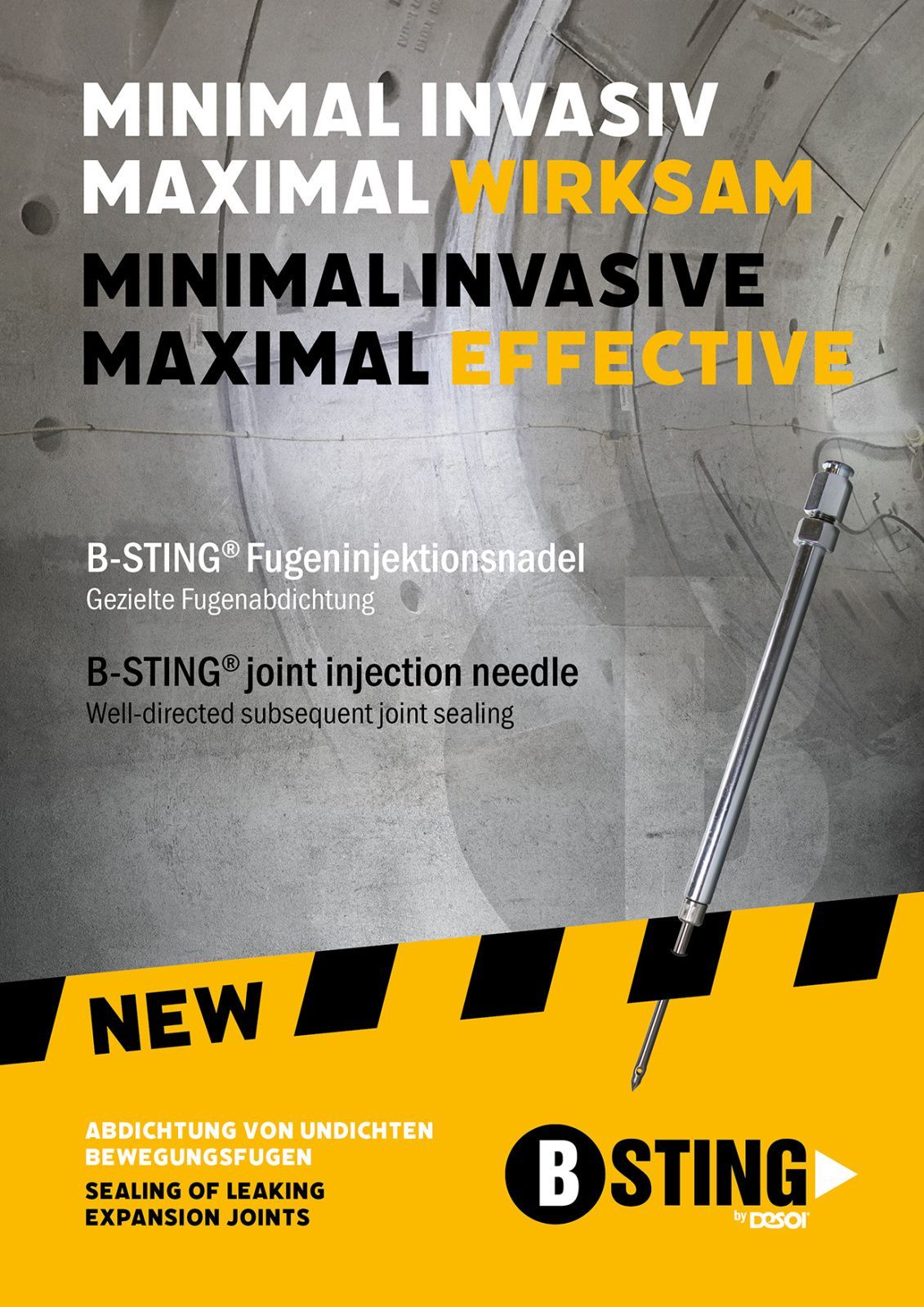

B-STING® joint injection needle

More Informations

B-STING® joint injection needle

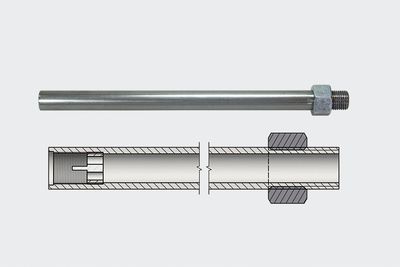

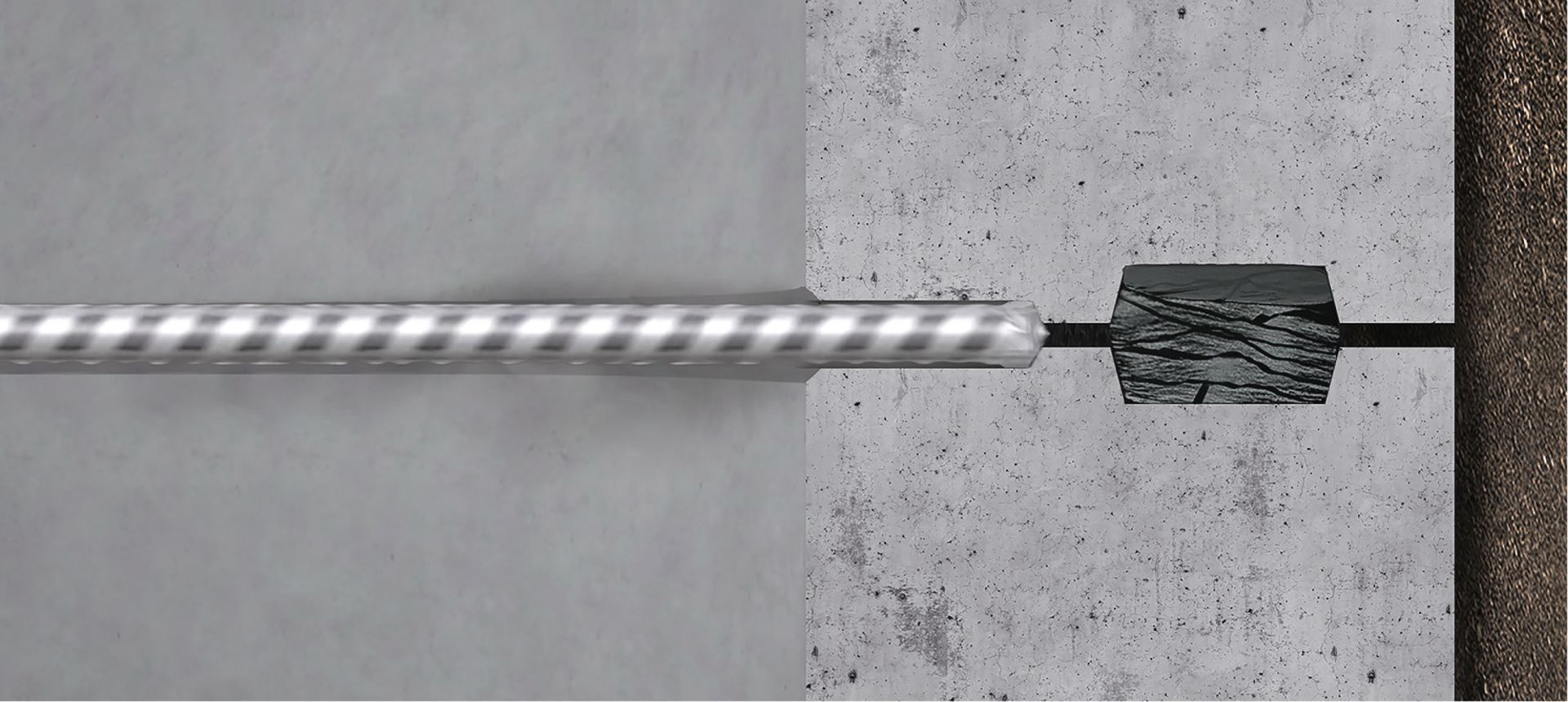

The B-STING® joint injection needle enables simple and safe sealing of sealing joints in tunnels, especially in segmental tunnels. The joint is sealed by screwing in the B-STING® with a cordless screwdriver and injecting an acrylate or polyurethane-based filler. The B-STING® remains in the component and ensures a permanent seal. There is no need for time-consuming drilling work during application.

NEW is the use of the B-STING® joint injection needle for sealing leaking expansion joints.

Minimal invasivE - maximal EFFECTIVE

advantages

advantages

- No drilling through reinforced concrete

- The B-STING®® joint injection needle penetrates the sealing element without removing any material

- No material removal => no leaks

Materials used

Materials used

- Acrylate gel

- Injection resin

Sealing of leaking

Segment joints

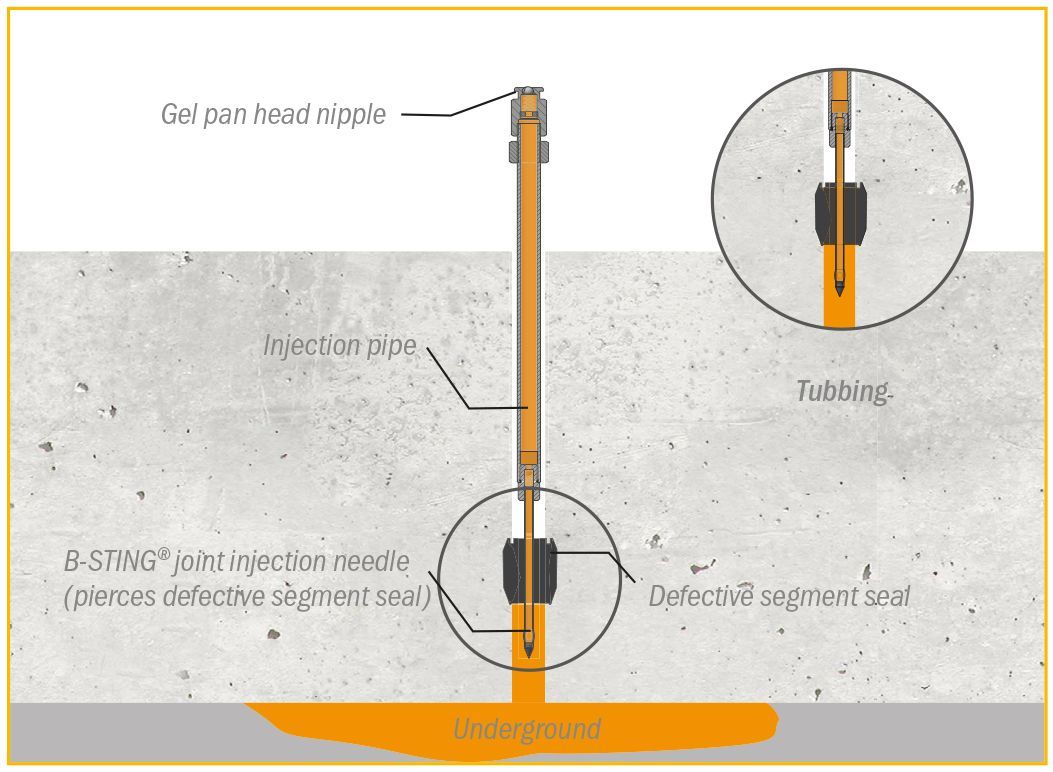

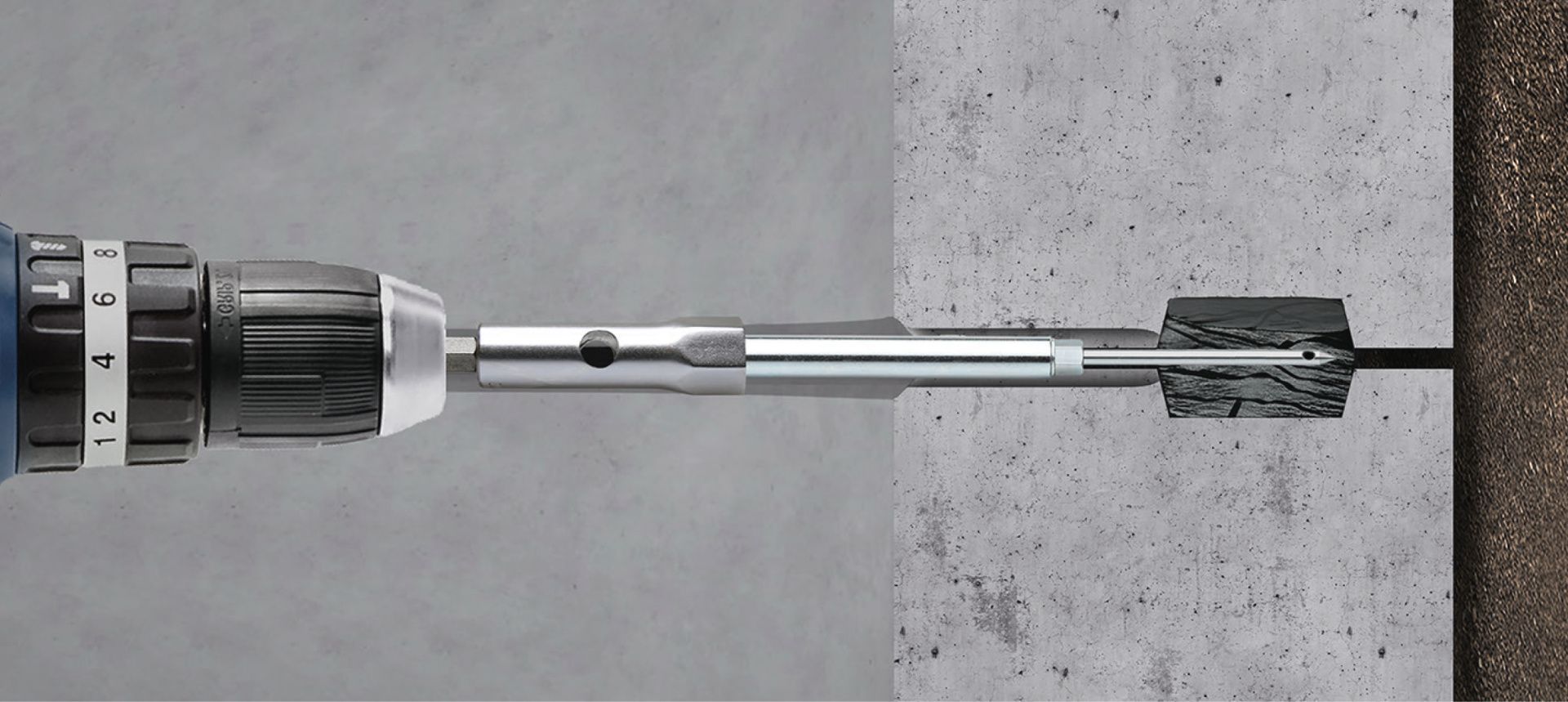

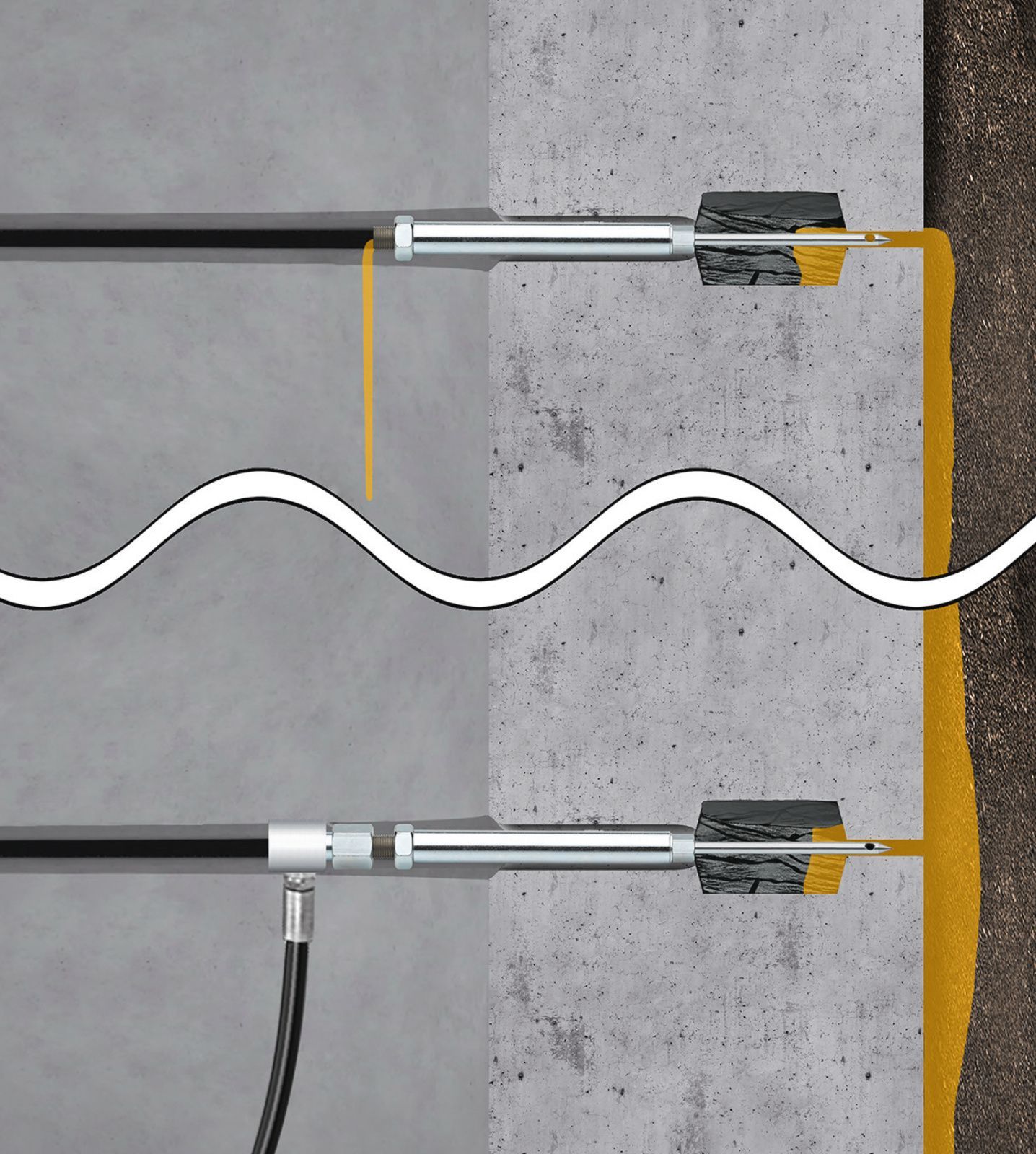

The procedure is basically identical for the subsequent sealing of segments. In this method, an approximately 5 mm thick joint injection needle is screwed into the segment seal via the segment joint using a cordless screwdriver and penetrates the segment seal. An acrylate or polyurethane-based fi ller is injected into the segment joint via a fl at-head gel nipple and the injection tube screwed onto the B-STING®. However, due to the smaller joint width, it is usually necessary to drill out the longitudinal or annular joints of the segments in order to be able to insert the injection pipe with the B-STING® joint injection needle into the joint. As a rule, a drill hole with a diameter of approx. 18 mm is su cient for this. The B-STING® joint injection needle remains in the segment seal and seals the hole permanently.

Sealing the joint in the case of a leaking segment joint using a B-STING® joint injection needle

Sealing of leaking

Expansion joints

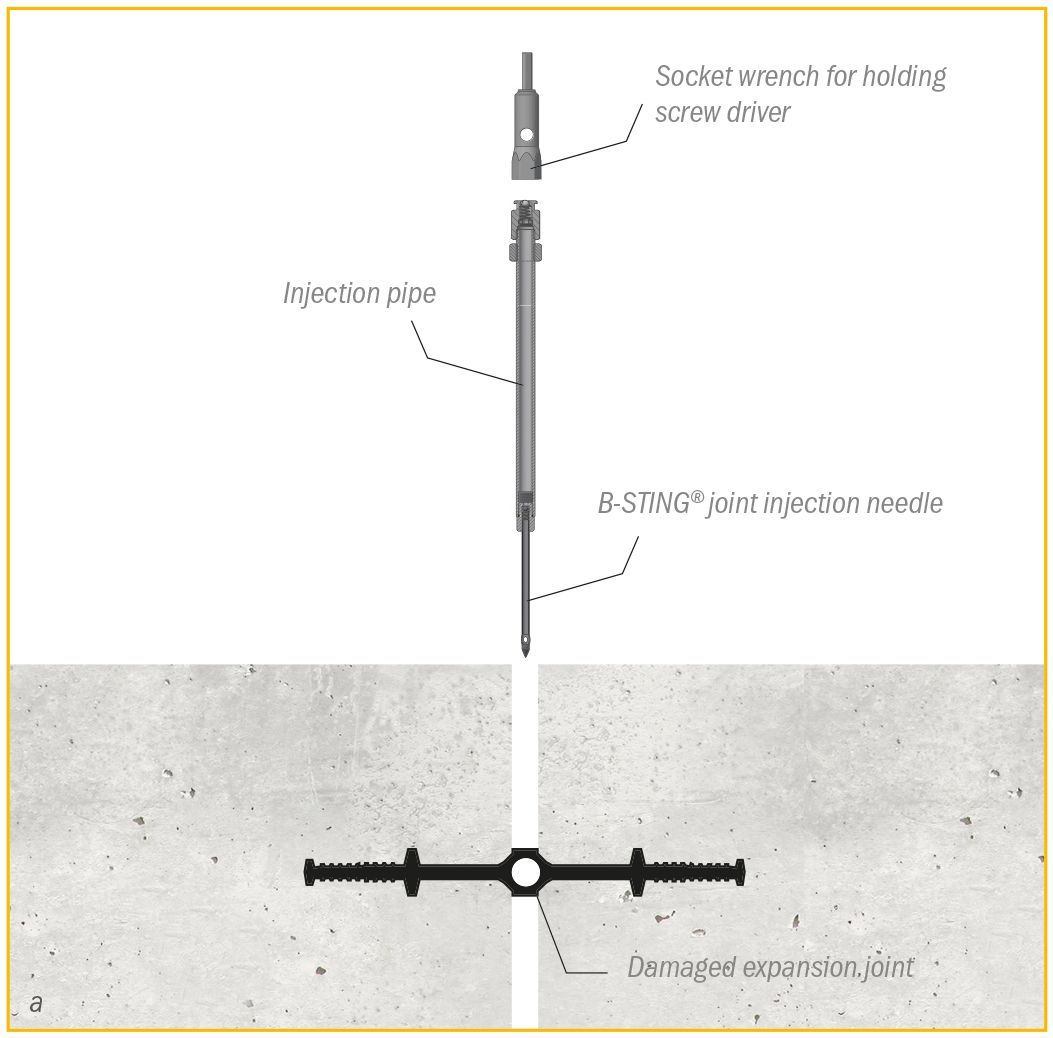

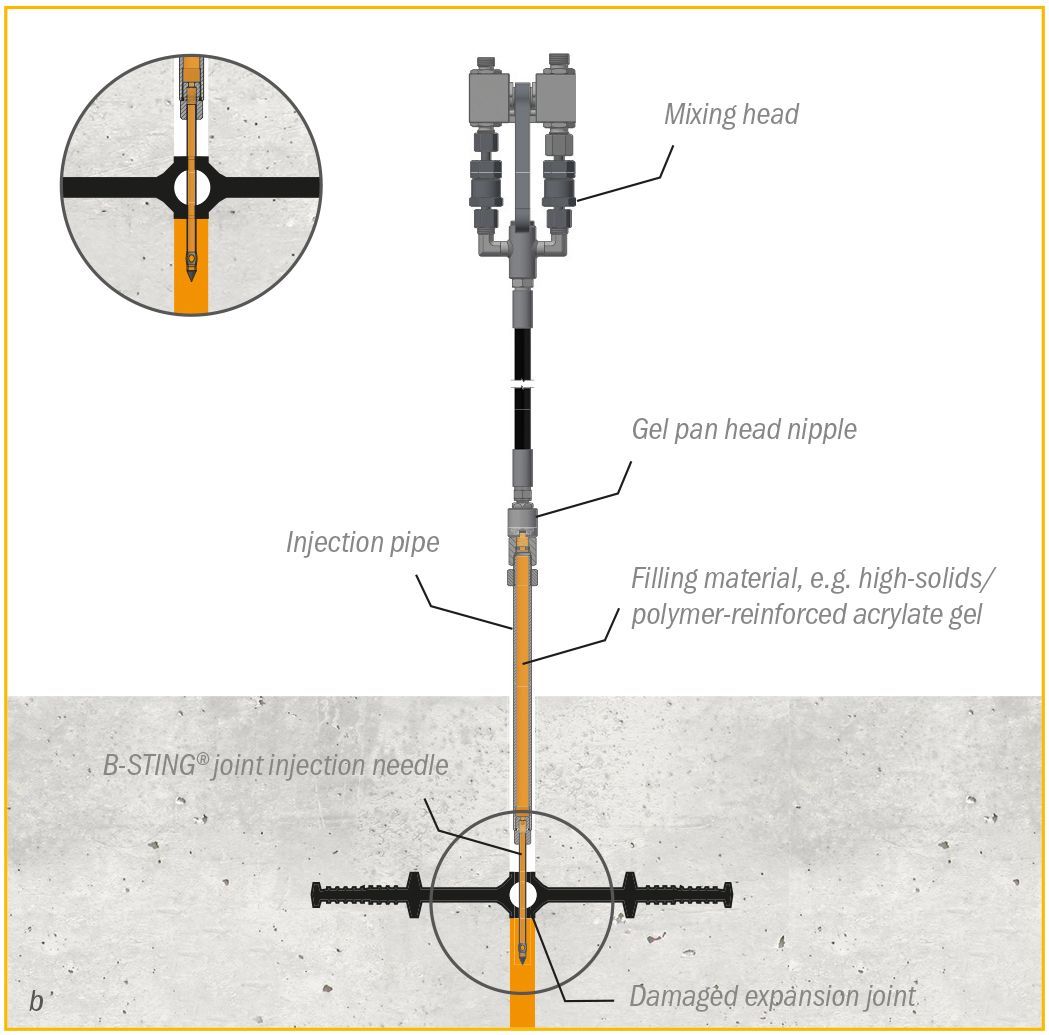

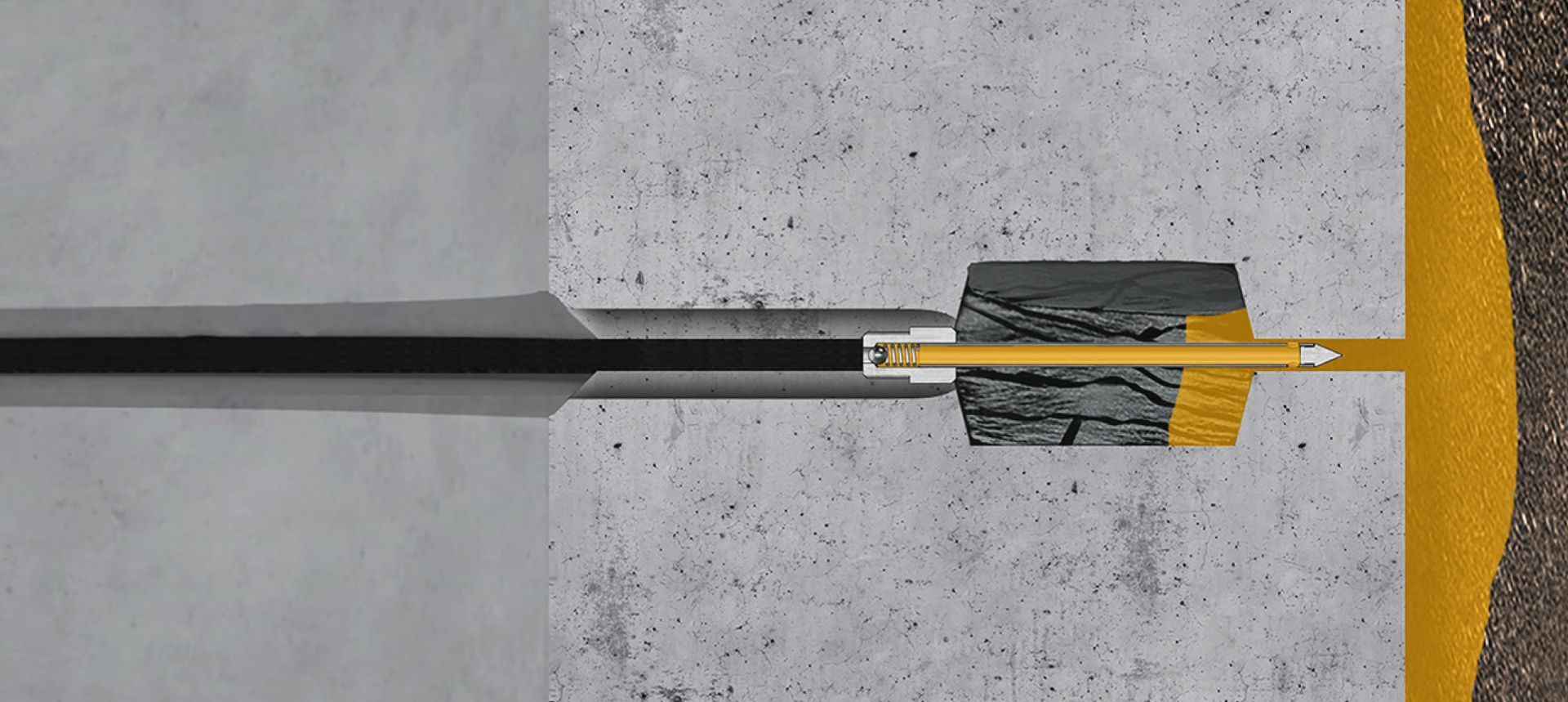

In this process, the B-STING® joint injection needle is screwed into the expansion joint through the sealing element using a cordless screwdriver. Injection is carried out into the water-facing side of the joint via a fl at-head gel nipple and the injection pipe screwed onto the B-STING®. After the injection process, the injection pipe is removed while the B-STING® remains in the seal and seals the injectionpoint permanently and water pressure-tight.

a) Positioning the B-STING® joint injection needle

b) Injection

WORKING STEPS

WORKING STEPS

➀ Drill down to the sealing element (This does not apply to expansion joints).

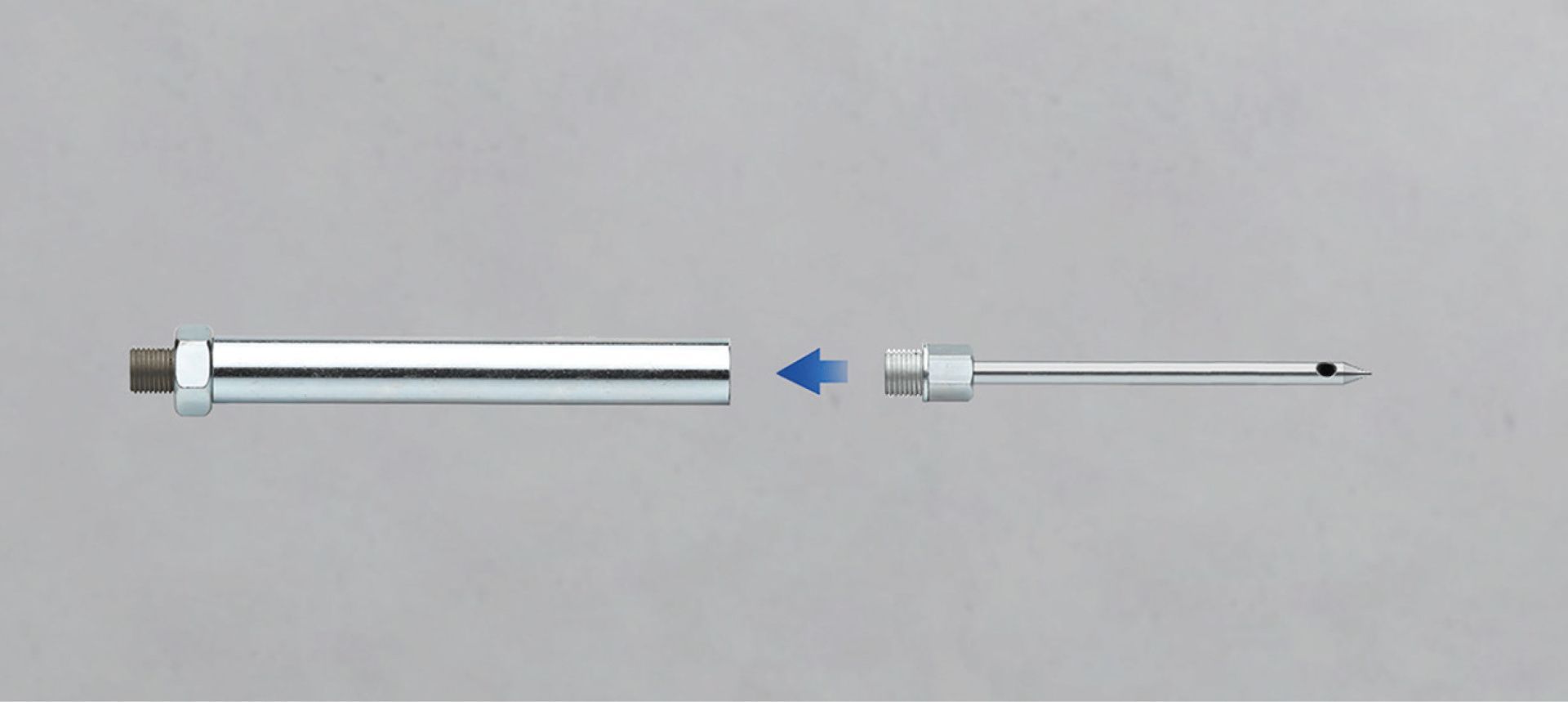

➁ Installing the injection pipe

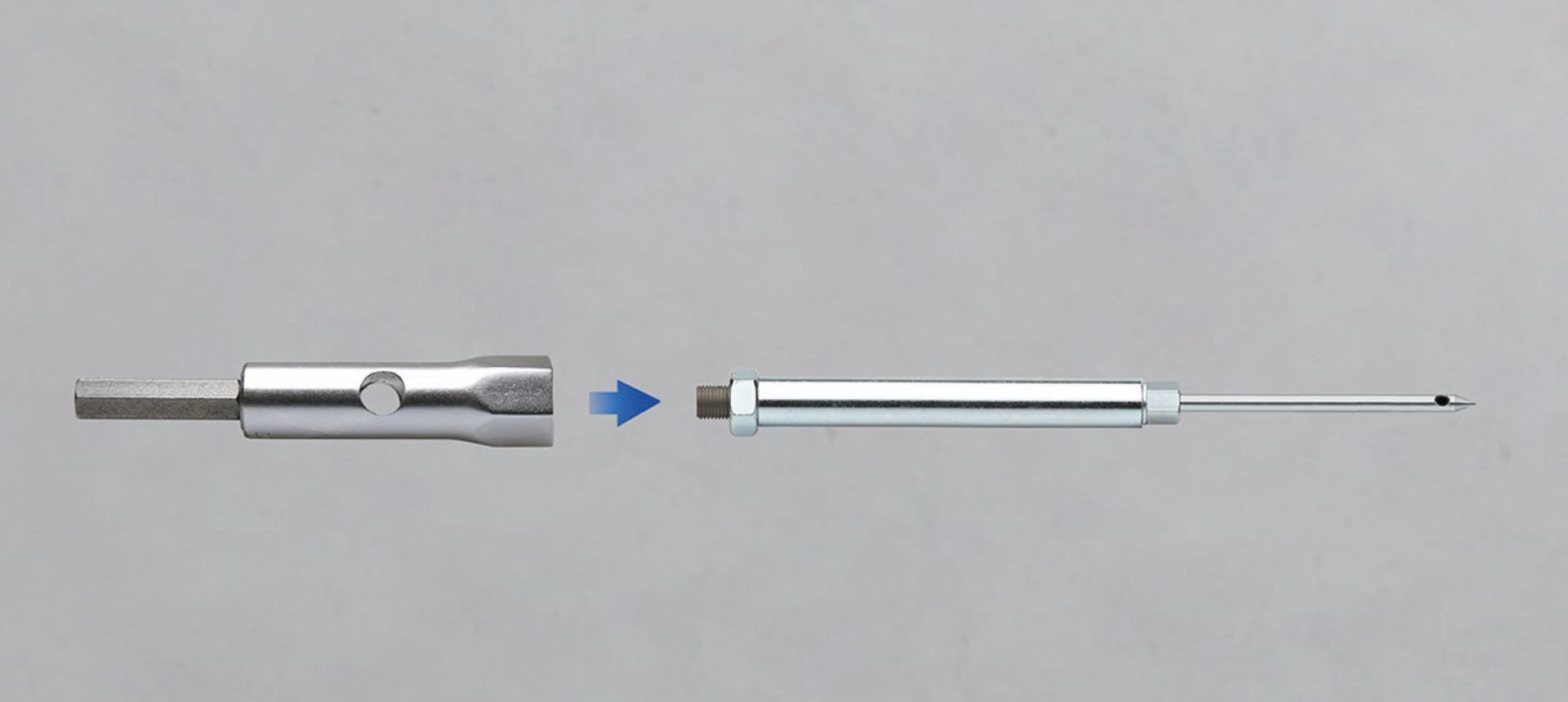

➂ Fit socket wrench

➃ Screw in with a cordless screwdriver

➄ Inject

➅ Inject until fi ller emerges from the next B-STING® joint injection needle

➆ Completed injection, B-STING® joint injection needle remains in the component